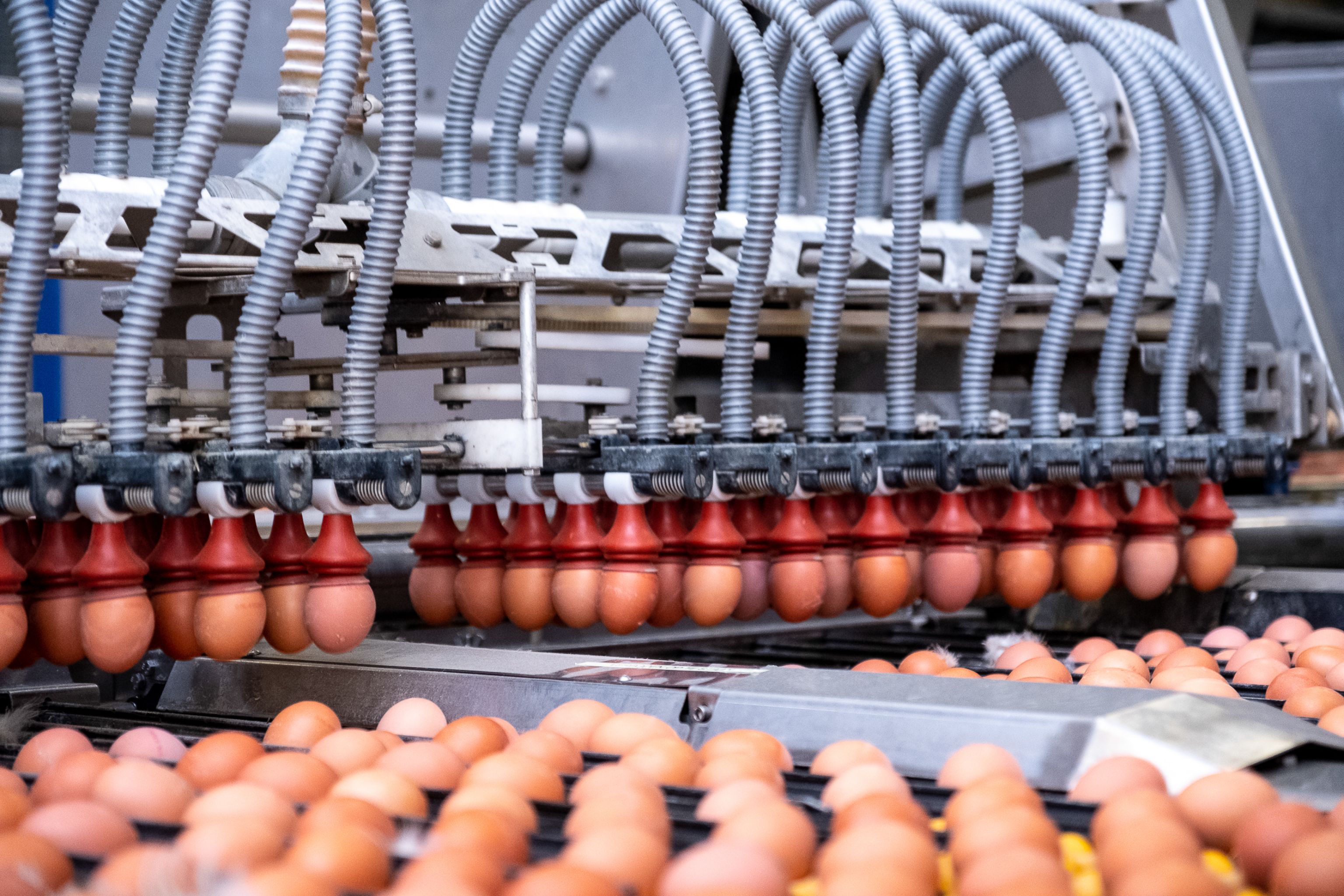

Grading machines

Our grading machines are an efficient way for us to manage product flows. We grade as many as 180,000 eggs every hour. We use data to continuously innovate the grading machines and the grading process itself. By doing this, we can guarantee the very best eggs and delivery.

Critical inspection

An electronic pump truck takes the pallets out of the warehouse. A robot arm then places the trays on the grading machine. The machine subjects each egg to a critical quality inspection. A camera zooms in on any breakages and checks for the presence of dirt on the egg. Rejected eggs are marked. Tiny microphones, combined with taps on the egg, determine the strength of each egg. Finally, each egg is weighed in the grading machine.

Moba works together to improve egg grading. We have been doing this for years with Kwetters.

Distribution of the eggs

After the inspection, we check which quality standards the eggs satisfy. The destination of the egg is then determined on the basis of that standard, so that every customer receives the eggs that he or she ordered.

Rianne Bouman

Kwetters